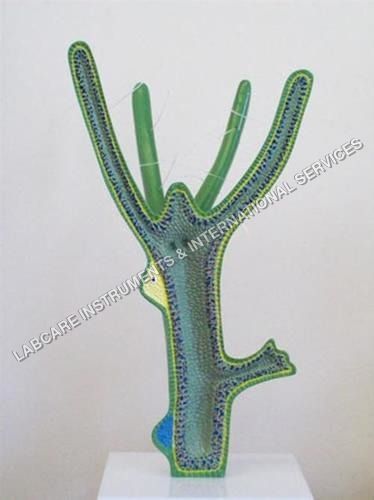

Hydra model

Hydra model Specification

- Style

- Contemporary Industrial

- Surface Finish

- Powder Coated

- Features

- High Flow Rate, Low Noise Operation

- Model No

- Hydra-1000X

- Size

- Standard Industrial Fitment

- Power Type

- Electric Motor Driven

- Assembly

- Pre-assembled Unit

- Use

- Water Pump Applications

- Weight

- 18.5 kg

- Type

- Centrifugal Pump

- Material

- High-Grade Cast Iron and Stainless Steel

- Dimensions

- 520mm x 320mm x 270mm

- Shape

- Rectangular Base with Cylindrical Body

- Color

- Blue/Grey

- Function

- Fluid Transfer and Irrigation

- Age

- All Age Groups, Industrial Use

- Advantage

- Corrosion and Abrasion Resistant

Hydra model Trade Information

- FOB Port

- MUMBAI

- Payment Terms

- Cash on Delivery (COD), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Letter of Credit (L/C), Cash Against Delivery (CAD), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 50 Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- card board packing

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO Certified product

About Hydra model

Engineered for Demanding Industrial Applications

The Hydra-1000X centrifugal pump is meticulously designed to meet the rigorous needs of industrial environments. Its high flow rate and superior construction materials ensure optimal performance, while advanced protection features like IP55 grading and powder coating enhance its resistance to challenging conditions. With a contemporary industrial style and standard dimensions, this pump integrates seamlessly into water transfer or irrigation systems.

Robust Build for Longevity and Safety

Manufactured with high-grade cast iron and stainless steel, the Hydra-1000X stands up to both corrosion and abrasion, ensuring minimal wear over time. Its air-cooled motor and IP55 protection support cool, safe operation, while the low noise level (<65 dB) contributes to improved workplace comfort. Designed for over 25,000 operational hours, this unit is an investment in long-term reliability.

FAQs of Hydra model:

Q: How do I install the Hydra-1000X pump in my facility?

A: The Hydra-1000X is a base-mounted, pre-assembled unit designed for easy installation. Simply position the pump on a stable foundation, connect the 1-inch BSP inlet and outlet, supply 220V AC single-phase power, and ensure adequate air circulation for cooling. For optimal performance, consult the manufacturers installation guidelines.Q: What are the primary benefits of using the Hydra-1000X pump?

A: This pump offers a high flow rate of up to 45 L/min with pressures up to 6.5 Bar, making it ideal for fluid transfer and irrigation. Its corrosion and abrasion-resistant materials, quiet operation, low maintenance requirements, and long service life provide efficiency and cost-effectiveness for industrial environments.Q: When should the Hydra-1000X be serviced or maintained?

A: With its low maintenance design, routine checks such as inspecting seals, bearings, and electrical connections are recommended every few months. Full servicing is typically required only after extensive use, considering its design for over 25,000 operational hours. Always follow the manufacturers maintenance schedule for longevity.Q: Where can the Hydra-1000X be applied most effectively?

A: This model is suited for a wide range of industrial water pump applications, including irrigation, fluid transfer, and general process water handling in factories or agricultural settings. Its robust construction withstands harsh industrial environments.Q: What is the process for replacing Hydra-1000X parts?

A: Replacement is straightforward thanks to the standardized design. Disconnect the power, depressurize the system, and replace worn components with genuine spare parts supplied by the manufacturer or authorized distributor to ensure compatibility and reliability.Q: How does the pump ensure long-term reliability and efficiency?

A: The Hydra-1000X utilizes high-quality cast iron and stainless steel material, a powder-coated finish, and IP55 protection to resist environmental damage. Its air-cooled motor and low-noise operation further promote a stable, efficient, and comfortable working environment.Q: What operational conditions are suitable for the Hydra-1000X?

A: The pump is engineered to function efficiently within an operating temperature range of 5C to 50C, supporting continuous duty in standard industrial or agricultural facilities without performance degradation or safety risks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Anatomical Models Category

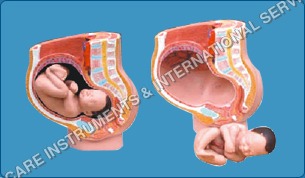

Female Pelvis model

Size : Lifesize

Type : Other, Physical anatomical model

Model No : FPM2024

Age : Suitable for all ages, mainly used by medical students and instructors

Features : Highly detailed, detachable parts, labeled anatomical features

Assembly : Preassembled, ready to use

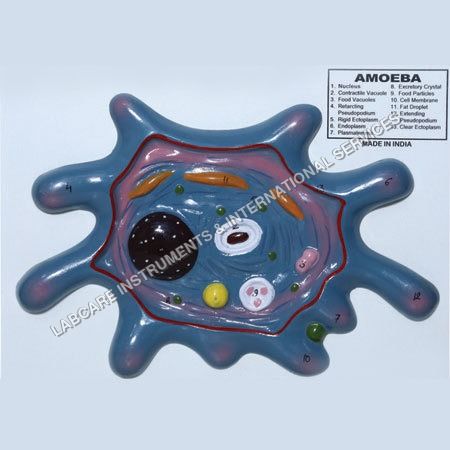

Amoeba model

Size : Standard (1300 mm Length)

Type : Other, Seesaw, Rocker

Model No : AMO601

Age : 28 Years

Features : Lightweight, Durable, Safe Design

Assembly : No assembly required

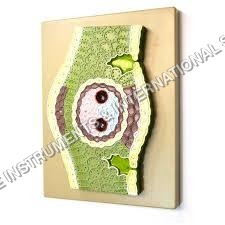

T.S. Monocot Leaf

Size : 75mm x 25mm

Type : Other, Botanical microscope slide

Model No : TSML01

Age : Suitable for all ages above 12 years

Features : Permanent mount, labeled, antifungal sealed

Assembly : Ready to use, no assembly required

Life history of Honey bee model

Size : 45 cm x 30 cm approx.

Type : Other, Biology teaching model

Model No : LHHB5925558

Age : Suitable for all age groups, ideal for students

Features : 3D depiction, segmented stages, labelled, sturdy base

Assembly : Preassembled (ready to use)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS