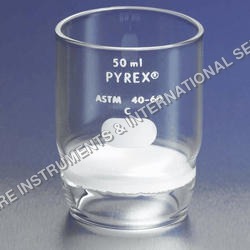

Sintered Crucible

Sintered Crucible Specification

- Features

- Thermal shock resistance, chemically inert, high mechanical strength, reusable

- Shape

- Cylindrical or conical based on application

- Temperature Resistance

- Up to 1200C or higher

- Heating Capacity

- Withstands rapid temperature changes, suitable for ashing and material synthesis

- Type

- Sintered Crucible

- Dimension (L*W*H)

- Varies by capacity (typically custom sizes available)

- Equipment Type

- Laboratory Crucible

- Equipment Materials

- Porcelain/Silica

- Power

- Not applicable (manual use)

- Material

- High-purity ceramic or porcelain

- Application

- Used for high-temperature material analysis, ashing, and laboratory heating procedures

- Capacity (Ltr)

- Available in multiple capacities (e.g., 10 mL up to 500 mL or custom sizes)

Sintered Crucible Trade Information

- FOB Port

- MUMBAI

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 50 Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- CARD BOARD PACKING

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO CERTIFIED PRODUCT

About Sintered Crucible

Leading Utility: The Sintered Crucible Advantage

The Sintered Crucible delivers excellence for both specific and general laboratory uses, supporting solid, liquid, and powder samples for analysis, ashing, or high-temperature processing. Constructed from high-purity porcelain or silica, it features low porosity and thermal expansion, ensuring reliable material integrity. Its unique designavailable in cylindrical or conical formsaccommodates custom or standard applications, making it a primary choice for material synthesis and laboratory investigations where consistency is paramount.

Secure Packaging & Prompt Dispatch

Our Sintered Crucibles are expertly packaged to guarantee shipping safety and integrity. Every shipment is handover-controlled and prepared for efficient dispatching, allowing for smooth transit across Indias main domestic markets. Goods are shipped promptly after order confirmation, with typical dispatch times minimized to expedite laboratory readiness. Packaging materials are selected to provide thorough cushioning, ensuring that goods remain in pristine condition upon arrival at your facility.

FAQs of Sintered Crucible:

Q: How does the low porosity of the sintered crucible benefit laboratory applications?

A: Low porosity ensures minimal sample absorption, preserving material purity during high-temperature analyses and preventing contamination in repeated use.Q: What types of samples can be processed using this crucible?

A: The crucible is engineered for solid, liquid, and powder samples, making it suitable for ashing, material synthesis, and various laboratory heating procedures.Q: When should a glazed or unglazed finish be selected?

A: Glazed finishes are preferred for easy cleaning and chemical resistance, while unglazed crucibles are chosen for applications where minimal surface interaction is desired.Q: Where can these crucibles be delivered or supplied?

A: We supply, export, and distribute our sintered crucibles across all major domestic markets in India, ensuring nationwide accessibility.Q: What is the process for customizing crucible dimensions and features?

A: Simply specify desired dimensions, capacity, wall thickness, and lid preferences during order placement, and we will manufacture to meet your exact laboratory requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory Glasswere Category

Distillation Assembly Consisting

Temperature Resistance : Up to 400C

Control Type : Manual Control

Type : Other, Distillation Assembly

Glass Type : Borosilicate 3.3

Material : Borosilicate Glass 3.3

Equipment Materials : Borosilicate Glass, Stainless Steel (frame/support)

Anderson Pipette

Temperature Resistance : Up to 250C

Control Type : Manual

Type : Other, Anderson Pipette

Glass Type : Borosilicate

Material : Highquality borosilicate glass

Equipment Materials : Borosilicate glass

Bulb condensor

Temperature Resistance : Up to 450C

Control Type : Manual handling

Type : Other, Bulb Condenser

Glass Type : Borosilicate 3.3

Material : Glass

Equipment Materials : Borosilicate Glass

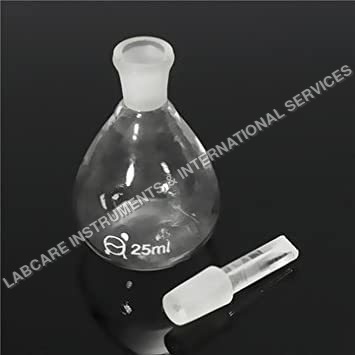

Pycnometer

Temperature Resistance : Up to 150C

Control Type : Manual

Type : Other, Pycnometer

Glass Type : Highquality borosilicate glass

Material : Borosilicate Glass

Equipment Materials : Glass

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free